MOST sells aqueous suspensions of nanoparticle oxides (2-10 nm diameter). Suspension stability is achieved by pH control. Suspensions include titania, silica, alumina, and select mixed oxide. Individual shipments are available for quantities up to 15 liters (4 gallons) per container. Zirconia suspension is available based on inventory.

MOST also has capabilities for using these suspensions to coat and fire selected materials, although these suspensions do not adhere well to plastics. Call 608-345-6678 or email walt@microporousoxides.com to discuss your proposed application.

NOTE: There are issues with shipping these aqueous-based suspensions in winter. Once these suspensions freeze, there is no guarantee that the suspensions will still be stable when thawed. Therefore, refrigerated shipment may be required.

More detailed information is provided below.

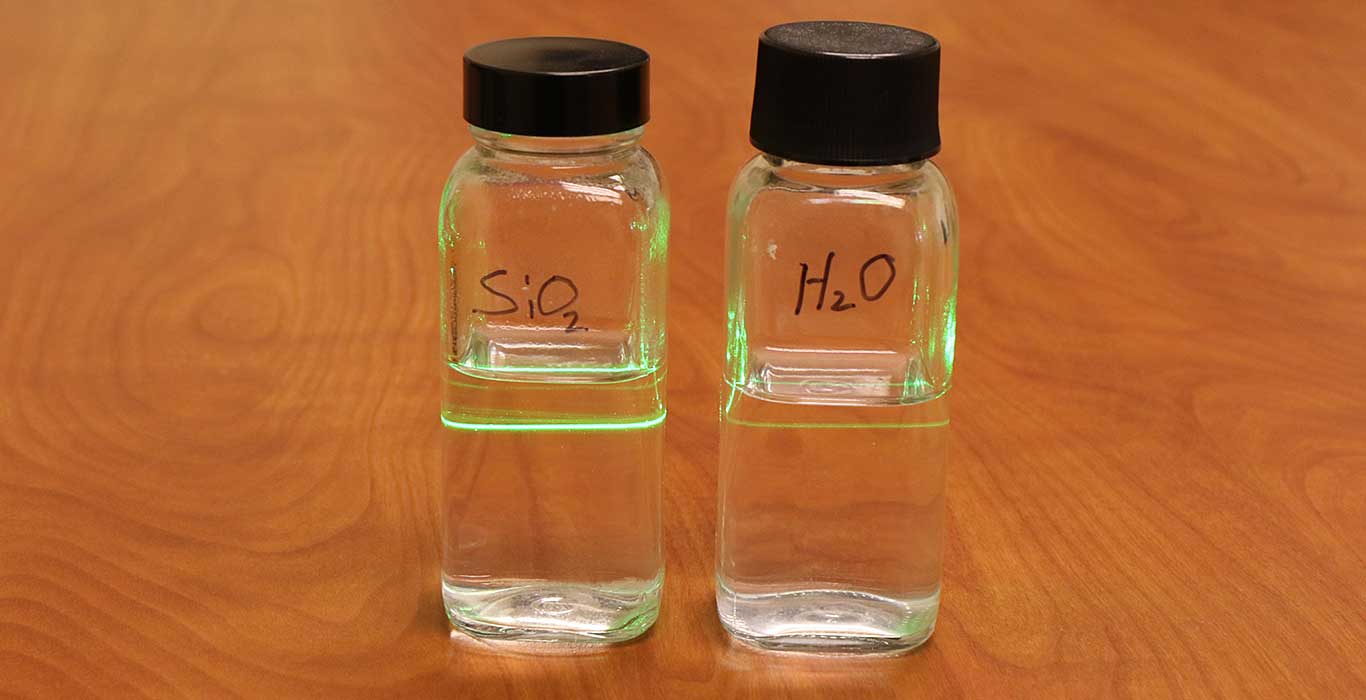

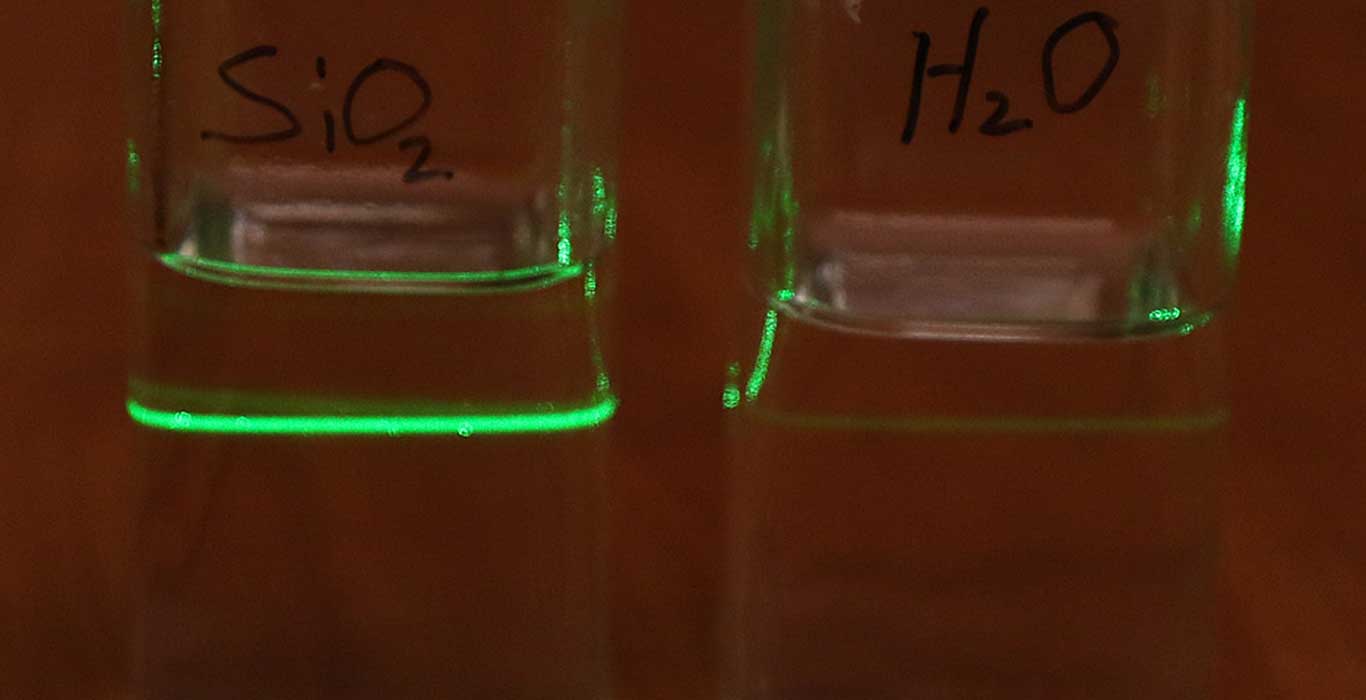

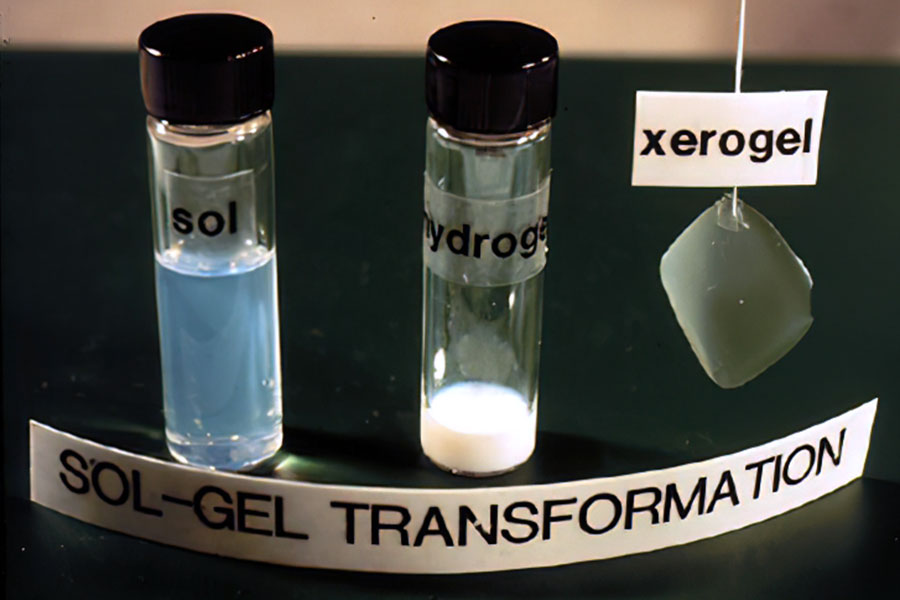

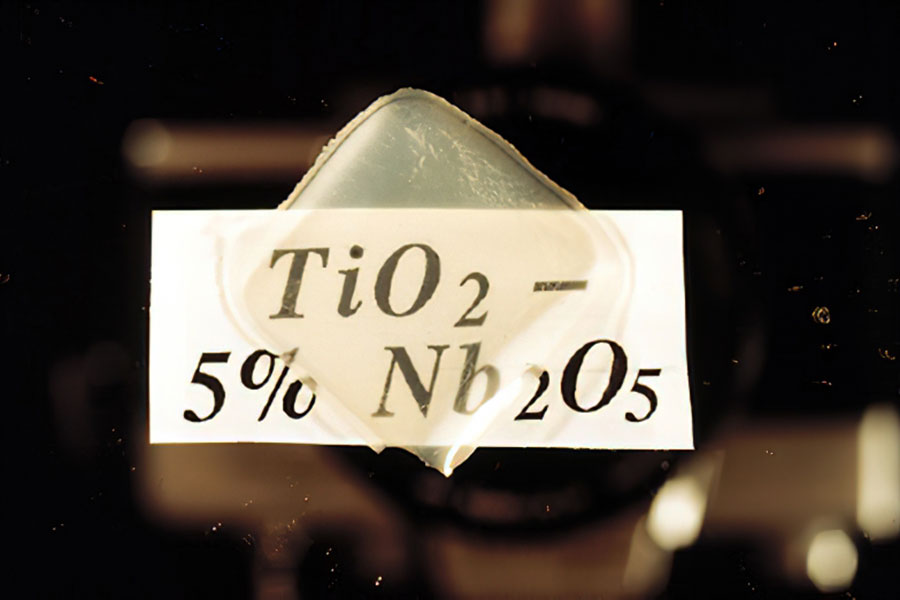

Fig. 1 below is an example of a stable suspension from MOST. In Fig. 2, the left vial is another stable suspension example. The center vial is a hydrogel produced by evaporation. Under controlled evaporation conditions, unsupported ceramic membranes can be prepared from hydrogels, as shown in Fig. 2 (right, xerogel) and Fig. 3. For an image of a ceramic membrane deposited on a porous ceramic support, see the “Ceramic Membrane” section of our Other Applications page (far right tube in first figure of that section).

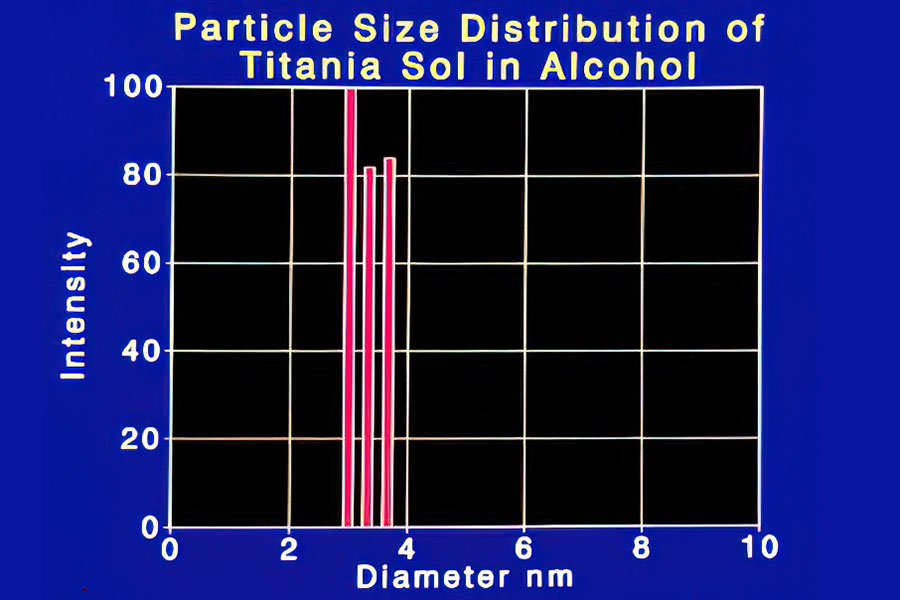

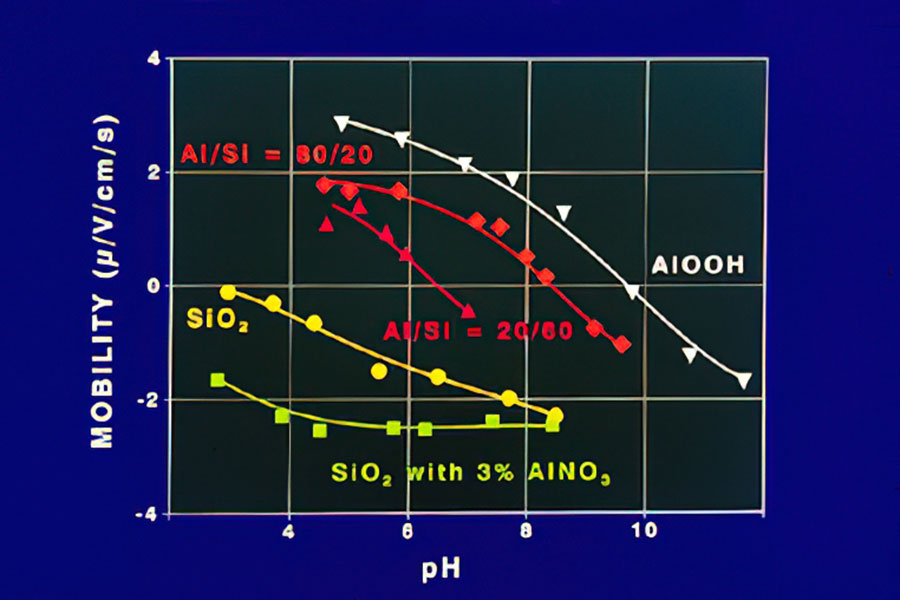

Fig. 4 illustrates particle size (approx. 3.5 nm diameter) of titania sols prepared in alcohol. Oxide particles in MOST aqueous suspensions are charged. Charge — related to electrophoretic mobility — depends on the pH of the water and varies depending upon the material, as shown in Fig. 5.

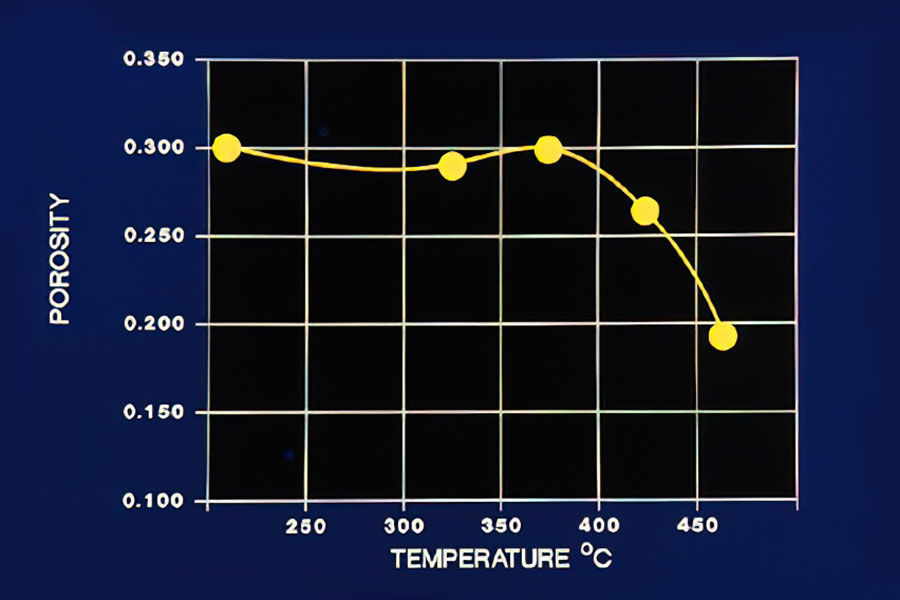

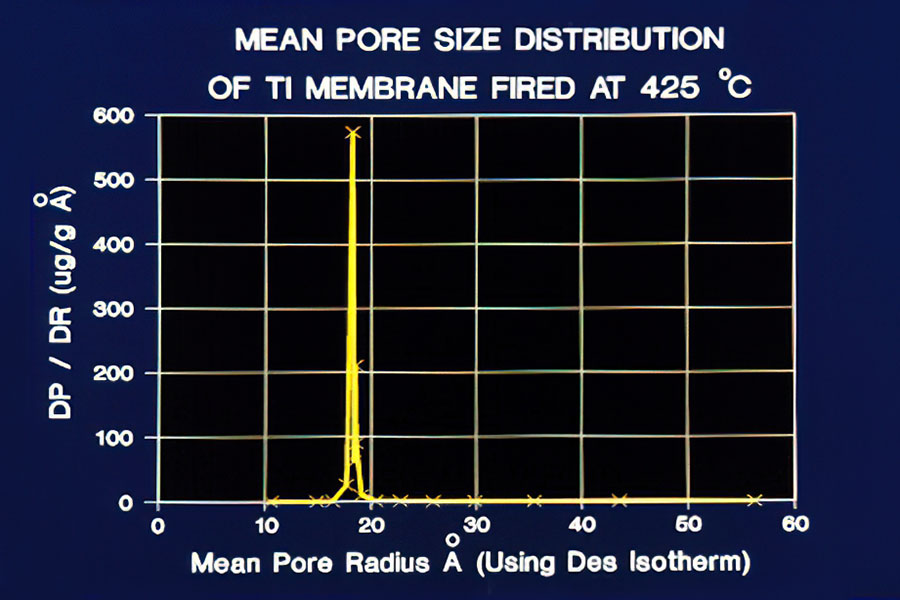

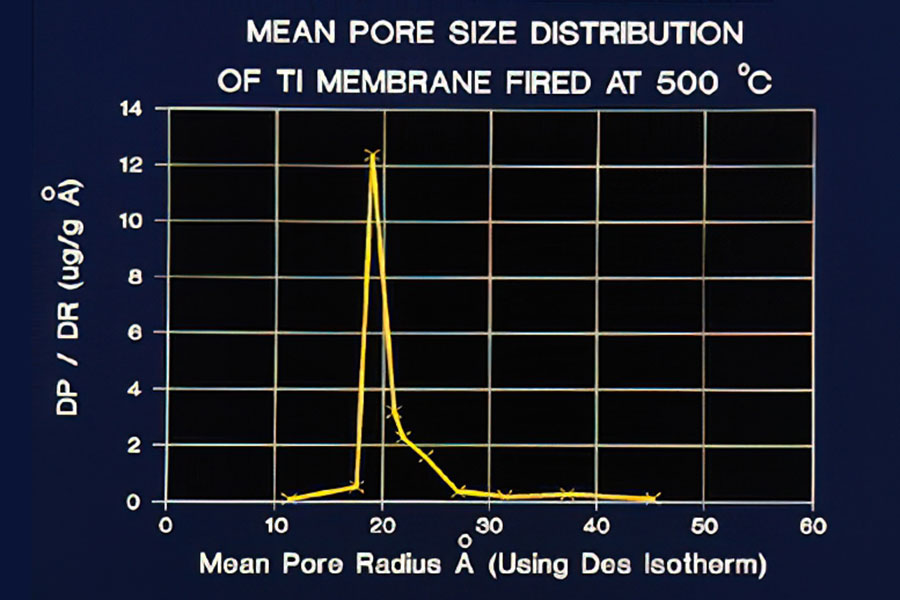

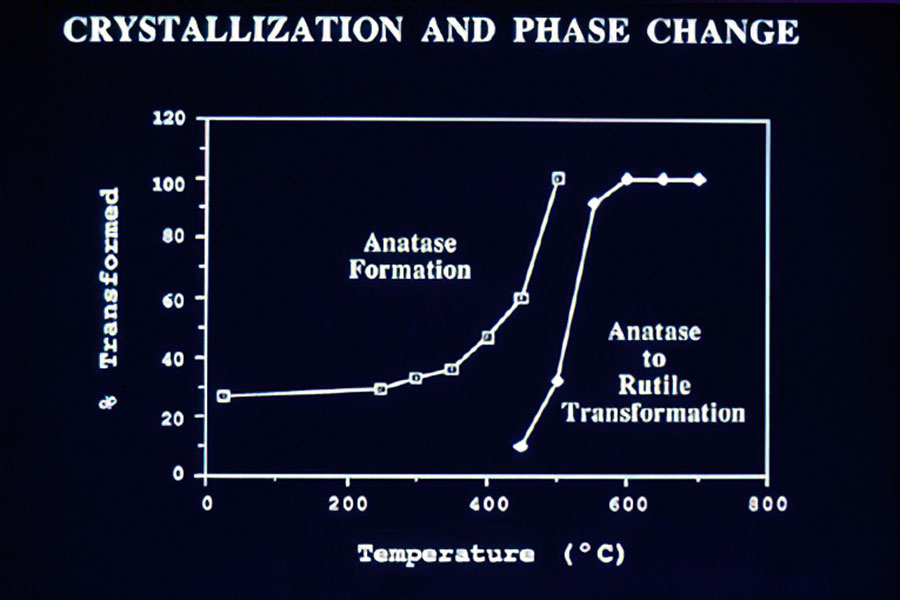

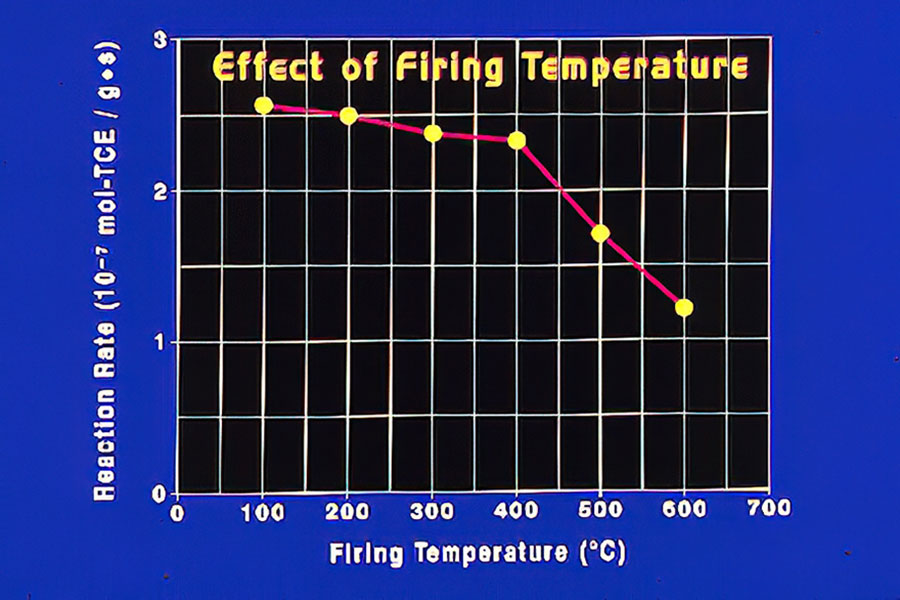

Solid materials prepared from these suspensions contain aggregated nanoparticles and are porous. Because they are porous, their properties (specific surface area, porosity, pore size distribution) depend on the temperature at which they are heated, as does their catalytic activity. Fig. 6 through Fig. 10 show examples of how firing temperatures affect these properties.

Such solid materials can be used as adsorbents for both gas- and liquid-phase applications. Bulk materials made from these suspensions can be expensive for general use as adsorbents. For this reason, MOST suggests that its materials should be used primarily as thin-film coatings on various supports.

Click any figure to zoom, click again to close.

Fig. 1

Fig. 2

Fig. 3

Fig. 4

Fig. 5

Fig. 6

Fig. 7

Fig. 8

Fig. 9

Fig. 10