We offer advanced water treatment through Capacitive Deionization or with Electrically Enhanced PCO. In either case, MOST nanoparticle materials bring you effective solutions for Water Purification.

Water Treatment Using Capacitive Deionization

Capacitive deionization (CDI) is a developing electrochemical technology for removing charged ions and higher molecular weight uncharged molecules from water. CDI purifies water by electrically removing ions without adding other chemicals.

In CDI systems, ions in the feed water flow through a highly porous pair of oppositely charged electrodes. Negatively charged ions are removed at the positive electrode while positively charged ions are attracted to the negative electrode, resulting in a cleaner product water. At some point during treatment, the electrodes become saturated, and no further purification can occur until the electrodes are regenerated by removing the adsorbed ions from the saturated electrodes.

Regeneration is often performed by simply turning off the voltage to the electrodes and allowing the adsorbed ions to diffuse back into solution. This process can be improved by incorporating nanoparticle materials prepared by MOST into the electrodes.

For more information, visit our sister company, Ur-Water LLC (ur-water.com).

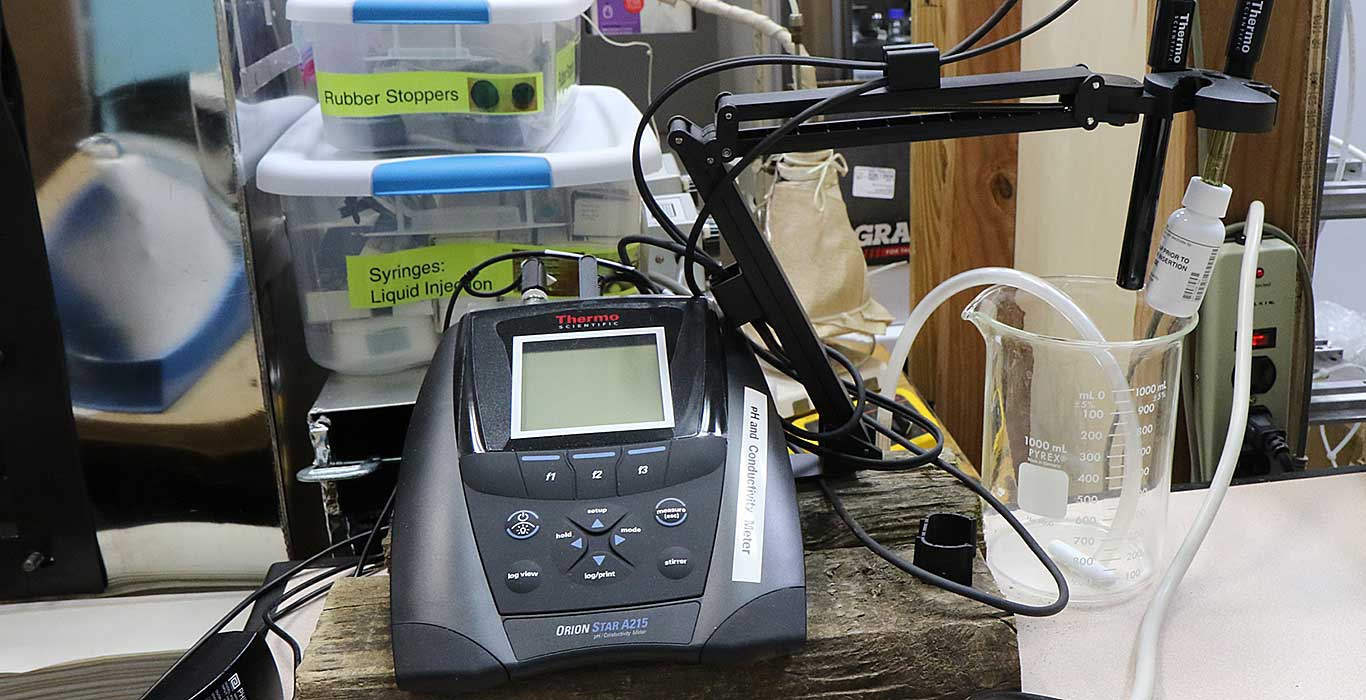

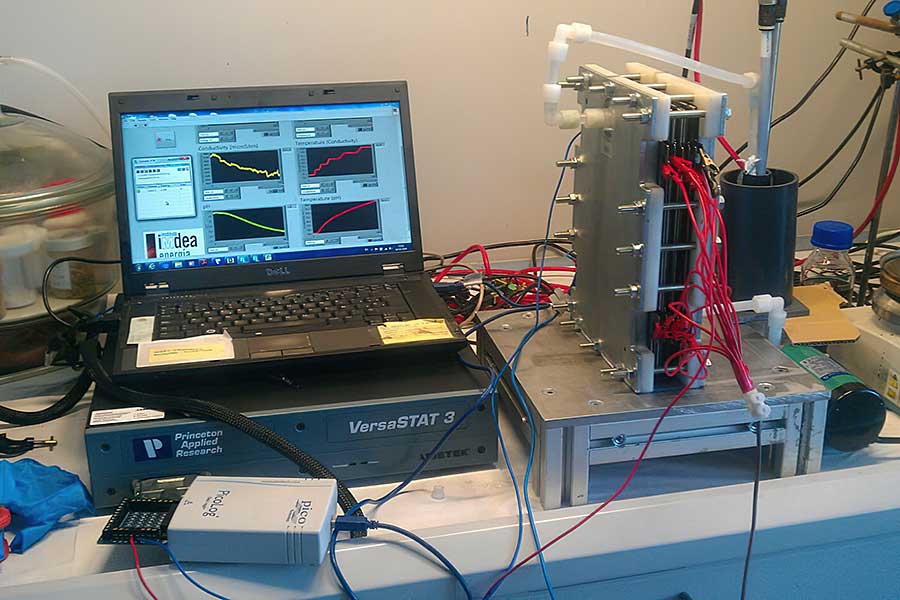

Capacitive Deionization Testing

Performance monitoring of Capacitive Deionization (CDI) test cells for water treatment. MOST provides materials that comprise CDI electrodes.

Water Treatment Using Electrically Enhanced PCO

We talk about photocatalytic oxidation on our PCO page where we focus on applications involving treatment of contaminated air. This focus occurs because oxygen gas is an important reactant in PCO. Since air contains 20% oxygen, there is an excess of oxygen available for PCO when used to break down contaminants in air. The use of PCO for treating contaminants in water was not discussed because of a lack of dissolved oxygen in water, as under the best conditions the amount of oxygen present in water is only about 0.003% unless additional oxygen is fed into the PCO reactor. Therefore, PCO reactions in water typically occur at a slow rate. In spite of this drawback, several companies offer water treatment systems based on PCO.

One method to increase the rate of PCO reactions in water is to electrically enhance the process by applying a voltage across two electrodes coated with a PCO catalyst. The applied voltage minimizes electron-hole recombination within the catalyst, allowing more of these reactive species to reach the catalyst surface and react with contaminants. This enhanced reactivity comes at the cost of complicating the design of the reactor.

For more information about electrically enhanced PCO, consult with the expertise at Exciton Clean LLC (excitonclean.com).