MOST was founded to sell oxide suspensions as catalytic coatings to purify carbon dioxide feed streams. The application note provides further details about an application involving CO2 purification. These coatings can also serve as general thermal catalysts.

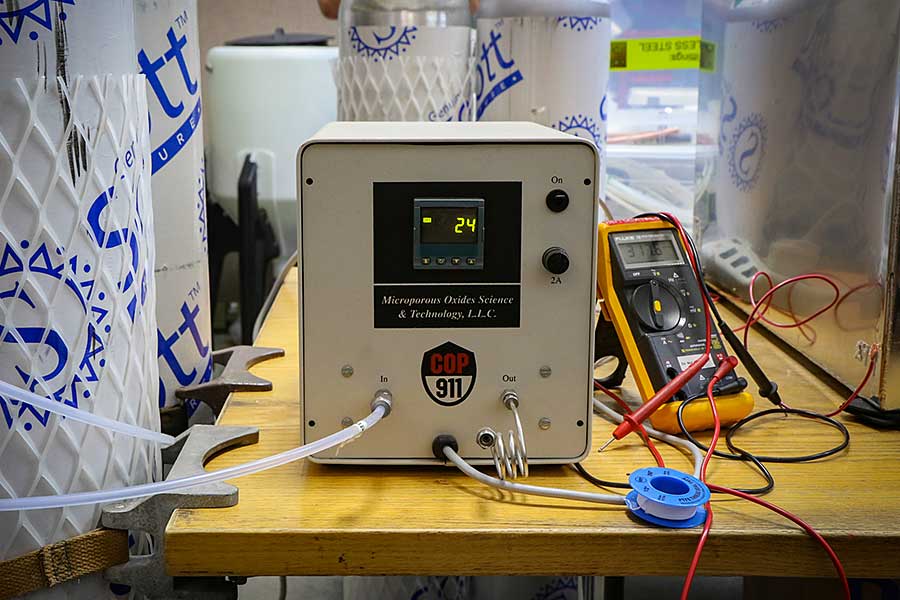

An early commercial product from MOST was the bench-scale CO2 purification unit shown here. The purification unit incorporates a catalyst that utilizes oxygen entrained in a stream of CO2 to oxidize trace amounts of hydrocarbons in the CO2, producing more CO2 and water vapor as reaction products.

As such, the purification unit acts as a final polishing step in treating hydrocarbon-based contaminants. Results from demonstration studies obtained with this unit are presented in the Application Note. A particular market for CO2 purification is precision cleaning of materials such as semiconductors.

Additional information for this application is found in Zorn, et al. (2012), In-line Catalytic Purification of Carbon Dioxide Used in Precision Cleaning Applications.

MOST employed thin-film coatings of these catalytic materials on commercial catalyst carriers (i.e., supports) to effectively purify a stream of CO2 produced by fermentation at a brewery. MOST can provide these coated catalysts, just send us a note for more information.